★Core Concept: Quantifies data's position within a group (similar to exam rankings but more precise)

★Calculation Formula

Standard Score = \(\frac{X - \mu}\sigma\)

Calculation formula:

\(Z = \frac{X - \mu}{\sigma}\)

(Tools available for automatic computation, no manual calculation required)

★Z > 0 = Exceeding industry benchmarks

(Example: A bubble tea shop’s daily sales Z=1.8 indicates 20% higher performance than district averages, enabling rapid replication of successful models)

★Z = 0 = Precise alignment with industry standards

(Example: Logistics companies use Z=0 to calibrate "next-day delivery success rates" and dynamically adjust resource allocation)

★Z < 0 = Risk warning signal

(Example: When a restaurant’s table turnover Z=-2.1, a 3-week optimization plan increased revenue by 23%)

Three methods:

★Health Management:

Height Z=1.5 (top 3% of peers) vs. Body fat Z=0.3 → Tailored fitness plans

★E-commerce Operations:)

✓ Inventory turnover Z=2.3 → Warns of bestseller stockouts

✓ Stockout rate Z=-1.8 → Triggers smart replenishment (37% reduction in losses for a leading platform)

★Manufacturing QC:

Product pass rate Z=0.8 vs. Energy efficiency Z=-0.5 → Prioritizes energy-saving upgrades

★Corporate Credit:Z < -3 → 82% cash flow crisis within 1 year (triggers loan management)

★Healthcare:Blood pressure Z < -2.5 → Activates AI pre-diagnosis

★Facility Maintenance:Z > 2.5 → 41% improvement in elevator failure prediction accuracy

\(Z = \frac{X - \mu}{\sigma}\)

Metrological Connotation of Parameters:

| Parameter | Physical Definition | Metrological Significance |

|---|---|---|

| X | Raw measurement value (Sensor output/Instrument reading) |

• Contains true value, systematic error (δ), and random error (εₐ) • Requires distinction between indication error and corrected value |

| \(\mu\) | Theoretical reference (SI unit definition/Calibration standard) |

• Traceable through metrological hierarchy • Must maintain 10x higher precision than σ |

| \(\sigma\) | Intrinsic uncertainty (Instrument resolution + environmental noise) |

• Evaluated per GUM Type A/B methods • Considers temporal drift and thermal effects |

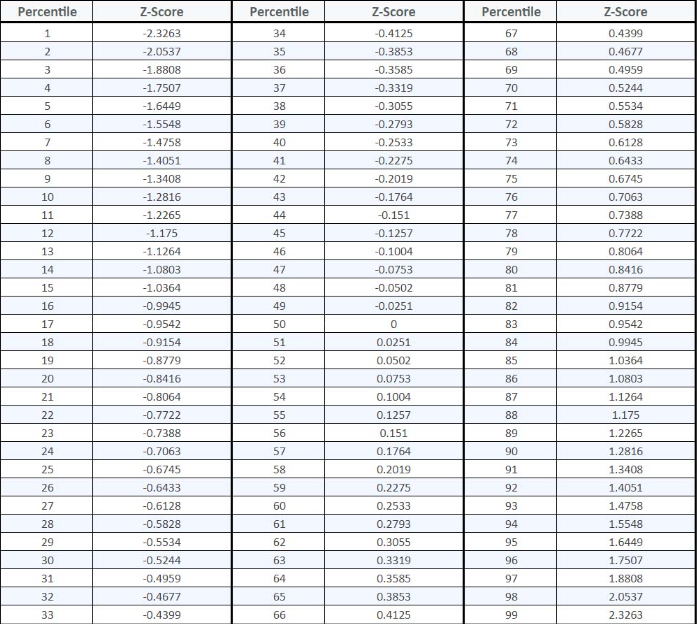

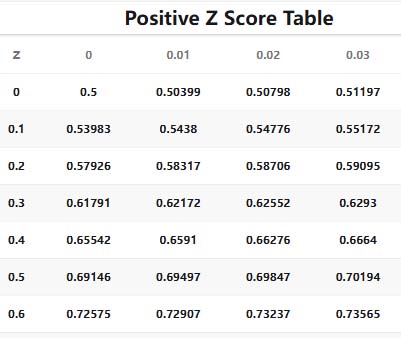

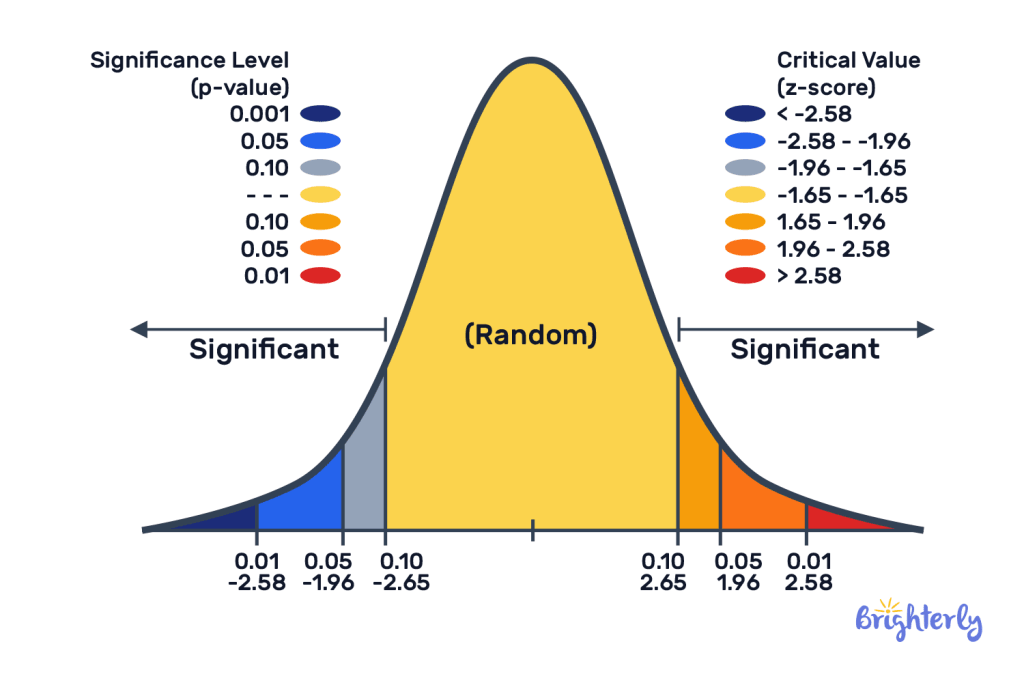

| Z Range | Statistical Significance | Universal Recommendations | Typical Applications |

|---|---|---|---|

| [3.0, +∞) | Top 0.13% of population |

1. Develop benchmark promotion plan 2. Establish abnormal return verification |

Historical peak performance indicators Special scenario detection |

| 1.96-2.5 | Significant difference (p < 0.05) |

1. Create strategy validation process 2. Initiate standardized replication |

Strategy effectiveness confirmation Quality certification standards |

| 1.28-1.96 | Exceeds 89.97% peers |

1. Allocate dedicated resources 2. Build advantage consolidation mechanism |

Top-tier resource selection Key talent identification |

| 0.5-1.28 | Above 68% industry baseline |

1. Optimize operational workflows 2. Develop best practice repository |

Performance reward thresholds Baseline evaluation metrics |

| 0-0.5 | Marginally above average |

1. Implement incremental improvement 2. Setup dynamic monitoring system |

New initiative pilot assessment Service compliance thresholds |

| -0.5-0 | Near industry norm |

1. Enhance process controls 2. Launch periodic review cycles |

Operational quality oversight Satisfaction baseline tracking |

| -1.28-0.5 | Below 31% competitors |

1. Conduct root cause analysis 2. Deploy emergency response resources |

Performance intervention points Quality alert management |

| -1.96-1.28 | Significant disadvantage (p < 0.05) |

1. Initiate corrective action plan 2. Execute cost restructuring |

Financial risk alerts Project termination criteria |

| [-∞, -2.5] | Extreme outlier |

1. Activate crisis management protocols 2. Execute organizational contingency response |

Survival risk warnings Life-critical medical indicators |